Polytetrafluoroethylene (PTFE) Is Used Extensively For Several Purposes Such As Making Non-Stick Cookware

|

| Polytetrafluoroethylene Market |

Polytetrafluoroethylene (PTFE) is used all

over the world, including in regions such as Germany, Mexico, and Singapore.

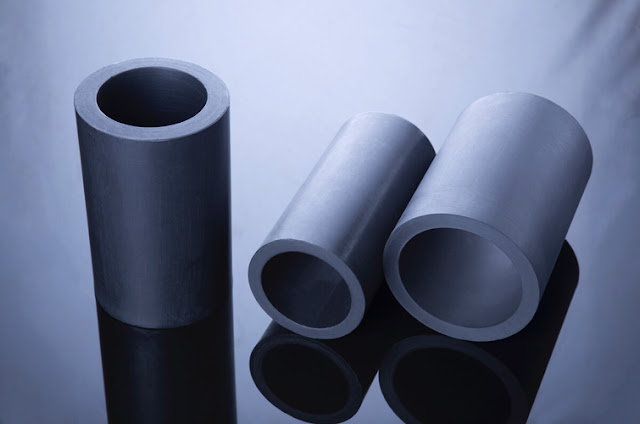

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of

tetrafluoroethylene. It is extremely durable and non-wetting, and it has high density.

It is also very conducive and has numerous applications in the medical field.

Its low friction and hydrophobic properties make it ideal for a variety of

mechanical engineering applications. In regions such as Germany, the increasing

prevalence of chemical companies has increased the usage of

polytetrafluoroethylene (PTFE). For instance, according to Germany Works, in

2019, there were around 2,900 chemical companies in Germany.

Polytetrafluoroethylene (PTFE) is often used

in electrical wiring as an insulator. Today, most types of coaxial cable are

made from PTFE. While its use in electronics has increased exponentially in

recent decades, its corrosive and flammable properties have prompted concerns

about the health risks of using polytetrafluoroethylene (PTFE). Although

polytetrafluoroethylene (PTFE) is not considered a biodegradable substance, it

does not need to be stored in a refrigerator. polytetrafluoroethylene

(PTFE) is also very flexible and can be used to make a variety of

products. Many people are concerned about the impact of PFOA on their health,

but the truth is that PTFE is one of the safest and most efficient chemical

compounds for use in electrical wiring.

The most common uses for polytetrafluoroethylene (PTFE) are in abrasives and

cleaning fluids. Its low dielectric constant makes it suitable for a variety of

applications. It is also a good choice for wire insulation and tapes. These

applications may be hazardous, but there are numerous uses for

polytetrafluoroethylene (PTFE) in the construction industry. Polytetrafluoroethylene (PTFE) is an

excellent material for a variety of medical applications. It is an

excellent insulator for electrical wires, and it is used in most types of

coaxial cables. During the Apollo 11 mission, it was also used to make the

computer wiring for the Apollo modules. Further, PTFE is used in the production

of a number of products that are safe and effective. These materials are

resistant to water and other substances.

Comments

Post a Comment